Xiaobian will introduce you to the impact of machining rough parts on cnc parts.

1. Affect the wear resistance: the rougher the surface of the CNC product is processed, the smaller the useful contact area between the mating surfaces, the greater the pressure, the greater the conflict resistance and the faster the wear.

2. Affect the stability of the fit: For the clearance fit, the rougher the surface, the easier it is to wear, so that the gap is gradually increased during the working process; for the interference fit, the fine peaks are flattened due to the fitting. Reduces the essential useful interference and reduces the connection strength.

3. Affecting fatigue strength: There are large troughs on the surface of rough parts. They are the same as sharp corner notches and cracks, and are sensitive to the stress set, thus affecting the fatigue strength of the parts.

4. Affect the erosion resistance: the surface of the rough part is easy to cause the aggressive gas or liquid to penetrate into the inner layer of the metal through the mesoscopic valley of the surface to form surface erosion.

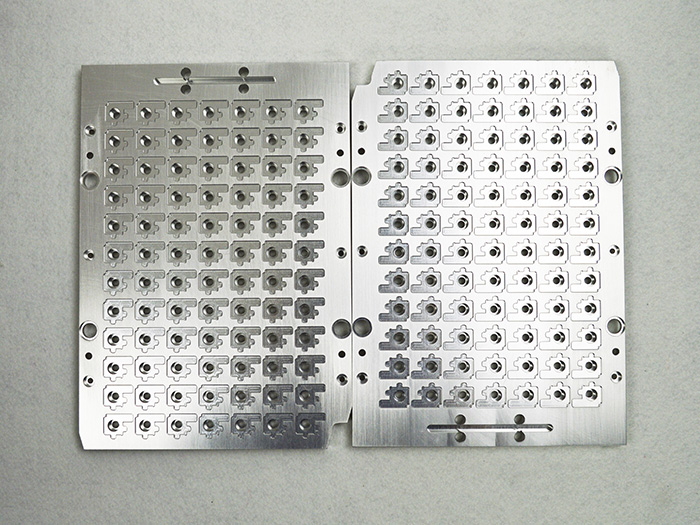

Kunshan cnc processing

5. Affecting the sealing property: the rough surfaces cannot be closely fitted together, and the gas or liquid leaks through the crack between the contact faces.

6. Affect the contact stiffness: The contact stiffness is the strength of the part fusion surface under the action of external force to resist contact deformation. The mechanical stiffness is at a very high level depending on the contact stiffness between the parts.

7. Influence measurement accuracy: The surface roughness of the measured surface of the part and the measuring surface of the measuring device will directly affect the accuracy of the measurement, and the measurement is more and more careful.

In addition, the surface roughness has a different level of influence on the plating, thermal conductivity and contact resistance of the part, the reflection strength and radiation function, the resistance of the liquid flow, and the smooth flow of the conductor surface. Therefore, Suzhou cnc processing plant should pay great attention to this aspect, and do not make the same mistakes in the production process.