1. Jog to the knife

The cnc processing equipment presses the jog key on the control panel to touch the surface of the workpiece (the two targets X and Z are jogged twice), the counter is cleared, and then retracted to the initial position to be set ( X, Z design initial value), and then clear to get the initial position of the knife. The initial position of each knife is confirmed in sequence, and then adjusted to the exact design position (starting point) after trial processing. This method does not require any accessories, it can be manipulated at the hand, but the time is long, the unique is that each time the tool is repaired, it must be adjusted once from the beginning.

2. Use the tool setting instrument

Nowadays, many lathes are equipped with tool setting instruments. The use of the tool setting tool can eliminate the deviation of the measurement, which greatly increases the accuracy of the tool setting. Since the tool setting instrument can automatically calculate the tool length and the knife width of each knife. The difference is stored in the system, and only the criterion knife is needed at the time of processing the other parts, which greatly saves time. The concern is that the use of the tool setting tool usually has no standard tool, and the tool is first used when the tool is turned. The disadvantage is that the tool for the knife is added to the tooling device, and the cost is high, and the loading and unloading is laborious.

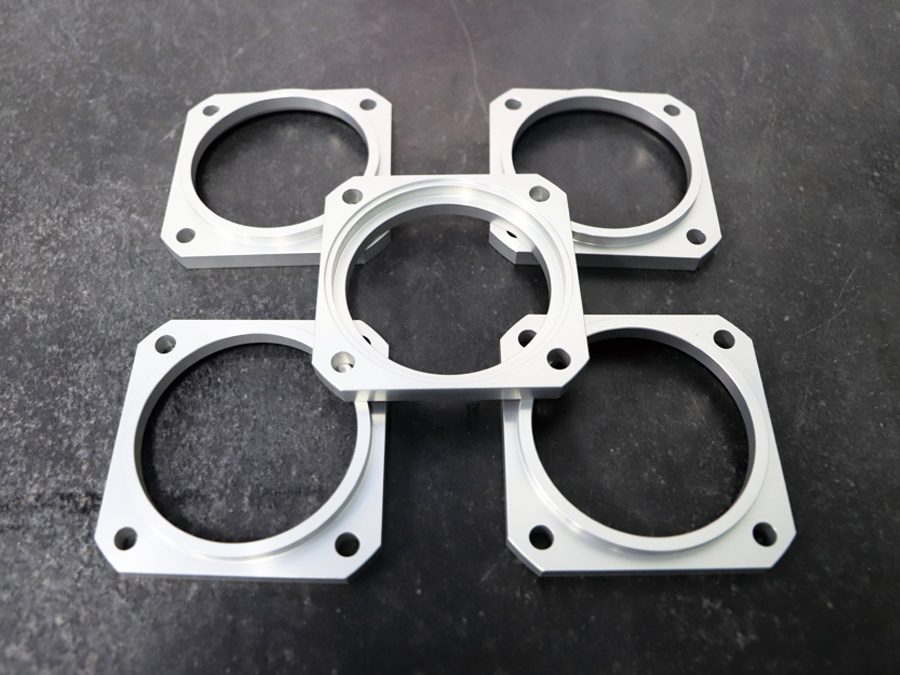

3. Select CNC tool

After the cnc machining tool is installed for the first time, it wears after a period of time cutting and needs to be sharpened. After the ordinary tool is sharpened, the position of the tool tip installed from the head is changed, and the tool is required to be cut from the head. The characteristic of the CNC tool is the tool manufacturing. High precision The positional accuracy of the blade after indexing is 0.02mm, which greatly reduces the time of the knife. At the same time, the blade is coated with a metal layer (Sic, Tic, etc.) to make the durability greatly increased, but the cost is also a bit high.

4. Use the tool holder to align the knife and select the automatic tool setting method.

The simple tooling block made of plastic, plexiglass, etc. simply completes the repeated positioning after the sharpening of the tool, but the positioning accuracy is usually 0.2~0.5mm, which is a rapid positioning method. It can be very quick and easy.